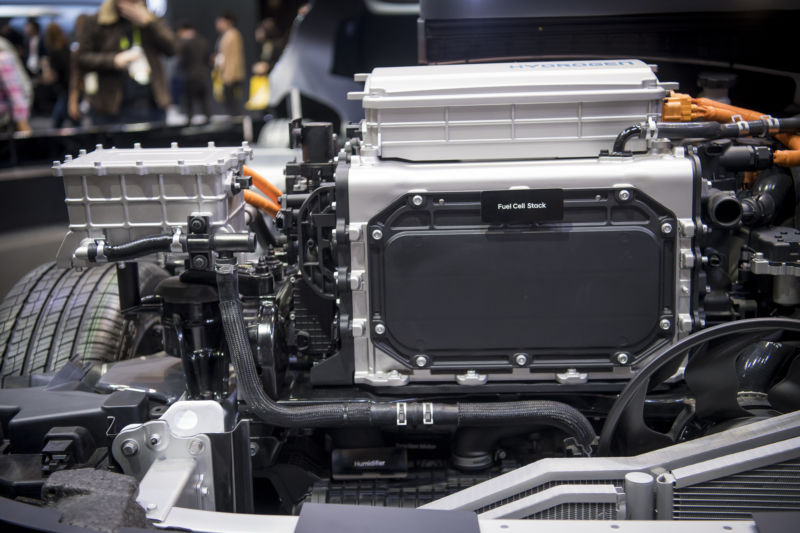

/ A fuel cell stack is displayed during the 2018 Consumer Electronics Show (CES) in Las Vegas, Nevada, on Thursday, Jan. 11, 2018.

On Monday, automotive parts supplier Bosch announced that it would be partnering with a company called PowerCell to manufacture fuel cells for commercial and passenger vehicles.

Currently, there’s not a huge market for hydrogen fuel cells, but a number of automotive leaders believe that hydrogen, which can be transformed into electrical energy through fuel cell stacks, will play a significant role in the transportation of the future if we want to curb carbon emissions in the face of climate change.

PowerCell, a Sweden-based company spun-off from Volvo in 2008, has been building hydrogen fuel cell stacks for a decade. Bosch has also worked to supply makers of fuel cell stacks. Together, the companies will jointly develop a polymer-electrolyte membrane (PEM) fuel cell stack for mass-production by 2022. (Currently, PowerCell manually produces its fuel cells, and it hopes to move to semi-automatic manufacturing as a result of its partnership with Bosch.)

“The joint development work will take the form of regular consultations among experts,” Bosch spokesperson Tim Wieland told Ars. He added that the two companies have no plans for a joint venture or a shared factory. When development is complete in 2022, Bosch will market the product to truck and passenger vehicle manufactures, and Powercell will market the product to “other industries,” according to Wieland.

“In the fuel-cell domain, Bosch already has a strong hand, and the alliance with PowerCell makes it even stronger,” Stefan Hartung, a member of the Bosch board of management said in a statement. “Commercializing technology is one of our strengths.”

Robert Bosch GmbH is a massive corporation with over 450 subsidiaries and local companies that provide a wide range of products and services to vehicle manufacturers, from component parts to software. (A branch of the company even wrote some of the code that helped Volkswagen and Audi diesel vehicles cheat their emissions tests.)

This means the company has been involved in a little bit of everything, fuel cells for vehicles included. Bosch’s most notable contribution to fuel cell deployment may be in its partnership with the hydrogen truck startup Nikola Motor Company. Bosch has a team of engineers at Nikola’s Arizona headquarters, working to get the company’s trucks over the production finish line.

Though there is a divide among alternative-fuel advocates over whether hydrogen fuel cells are the future or all of them should be scrapped in favor of battery-electric vehicles, Bosch clearly believes that hydrogen fuel cell technology has a real future in the trucking industry. “Over the long term, the mobile fuel-cell business is potentially worth billions of euros for Bosch,” a company press release states. The company estimates “that as much as 20 percent of all electric vehicles worldwide will be powered by fuel cells by 2030.”

Still, it’s unclear whether a Bosch-and-PowerCell fuel cell stack would actually be used in the United States as long as Nikola remains the primary driver of the hydrogen fuel cell trucking dream. In early April, PowerCell (which had also been working with Nikola to design a heavy-duty truck fuel cell) announced that it would part ways with Nikola because “PowerCell could not accept Nikola’s terms for a continued cooperation.”

Nikola says…

When Ars contacted Nikola for clarification about which company would design its trucks’ fuel cell stacks, Nikola CEO Trevor Milton responded “We are very proud of our strong relationship with Bosch. As previously announced, we are not working with PowerCell. We are going in a different direction with our fuel cell stack, which we will announce when the time is right.”

Whether the fruits of a Bosch-PowerCell alliance can be realized in the US or not may still be up for debate. But Bosch clearly sees a market in Europe for its technology. “The EU’s fleet requirements for trucks call for a reduction of CO2 emissions by 15 percent on average by 2025 and 30 percent by 2030,” Bosch wrote in a press release. “Bosch’s view is that this target can only be reached by electrifying more and more of the powertrain. The fuel cell can play a decisive role here.”

Bosch says that two-thirds of the cost of a fuel cell system is found in the fuel cell stack, so achieving economies of scale through manufacturing development is key to reducing the cost of hydrogen fuel cell trucks and other vehicles. And if the fuel cell can be mass-manufactured, then all that remains is figuring out how to make cheap, renewable hydrogen easily accessible on any road.